Scientific LCA study highlights copper’s superior properties as the material of choice over plastic

The buildings and construction sector accounts for about 35 percent of energy use and creates 40 percent of global energy and carbon dioxide (CO2) emissions annually. Building operations are responsible for 28 percent of the emissions each year, while manufacturing building materials and the construction process (also referred to as embodied carbon) are responsible for an additional 11 percent.

Embodied carbon emissions are locked in place as soon as a building is built and cannot be reduced through improvements to energy efficiency or by introducing renewable energy systems. Therefore, building construction products (e.g., piping in an apartment) with lower emission impacts are key in addressing embodied carbon.

Research conducted by ICA in collaboration with Sphera and led by Dr. Constantin Herrmann examined three water installation tube systems—copper, plastic multilayer pipes (PEX-Al) and plastic cross-linked polyethylene (PEX)—via a scientific life cycle assessment (LCA) comparison in accordance with ISO14040.¹

The comparative findings, backed by a scientific review panel, definitively concluded that only a copper system ensures high levels of recyclability and material circularity that significantly reduces the environmental impact of a building.

The comparative research shows that when copper is intelligently used in buildings, it reduces CO2 emissions and supports the 1.5°C goal to mitigate climate change and global warming, as stated by The Intergovernmental Panel on Climate Change (IPCC).

A focus on CO2 emissions and primary energy reduction

An LCA assesses the environmental impact of a product from its creation through its use and eventual deconstruction or disposal. Sphera’s LCA study compared three water installation tube systems to determine if the production, lifetime use and deconstruction were comparable for all three systems. The LCA researchers investigated the comparative water use for a 100m2 (~1,076ft2) apartment and covered tubes and additional system components, such as fittings and connectors that combine and fix the tubes. The key variables for comparison included the material’s composition and properties, manufacturing and respective recycling potential.

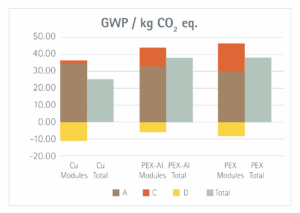

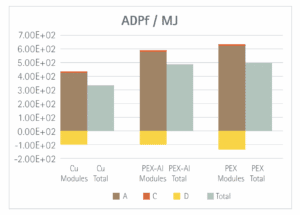

Study findings indicate that using copper in a building’s drinking water system cuts around one-third of Greenhouse Gas emissions (GHG, Graphic 1) and energy use (Graphic 2) compared to systems made from plastic (PEX-Al and PEX). This is true not only for a drinking water system, but in every application where copper tubes are used to transport fluids in buildings (e.g., heating, air conditioning and gases).

Graphic 1: Global Warming Potential (GWP) results from the comparative LCA study (2021)

Graphic 2: Resource use, fossil fuels and energy carriers, Abiotic Depletion Potential fossil (ADPf)

Copper cuts operational and embodied CO2 emissions

When it comes to operational emissions, copper’s intrinsic properties provide additional GHG savings. For instance, in the EU, heating, cooling and domestic hot water account for 80 percent of household energy consumption. Waste Water Heat Recovery (WWHR) is an available and effective energy-efficiency solution to reduce the energy demand for domestic hot water via direct heat recovery from shower drains. Copper’s excellent thermal conductivity saves approximately 40 percent of energy use and CO2 emissions from domestic hot water production. The combined operational and embodied carbon savings make copper a key contributor to decarbonizing buildings.

As presented in the study, additional emission reductions can be achieved through copper recycling, conservation and material circularity. Copper can be recycled over and over again without any loss of its properties. By pursuing responsible sourcing and recycling practices across the copper value chain, copper will continue to be the material of choice for sustainable decarbonization technologies.