By working together, industries can reduce waste by finding applications for byproducts of production, or repurposing products at the end of their life for re-entry to the supply chain.

For industrial symbiosis to occur, the following conditions must be met:

- A symbiotic relationship between two actors (resource producer, i.e., seller, and resource user, i.e., buyer) that operate in close geographical proximity

- Mutual environmental and socio-economic benefits, such as reducing the environmental/carbon footprint and costs, for participating industries (this can be quantified through a Life Cycle Assessment (LCA), cost-benefit analyses and market analyses)

- Access to sufficient, transparent and tangible information to create certainty and trust; and

- A regulatory framework that facilitates and incentivizes industries to cooperate in maximizing the use of secondary materials (e.g., byproducts or embedded materials in end-of-life products)

If these conditions are met, industrial symbiosis has the potential to become a fundamental circular solution with significant benefits. From an environmental point of view, industrial symbiosis contributes to reducing the environmental and carbon footprint of products and companies by extending materials’ lifetimes and minimizing waste. Economically, industrial symbiosis comes with cost savings. It helps companies avoid the high costs of virgin raw material mining extraction and of waste landfilling, and it creates more jobs by increasing the revenues for participating businesses and local communities. Overall, industries’ cooperation in the use of resources contributes to the promotion of key United Nations’ Sustainable Development Goals (SDGs), such as those for decent work and economic growth, industrial innovation, climate action, and responsible sourcing and production.

Opportunities for Industrial Symbiosis in the Copper Industry

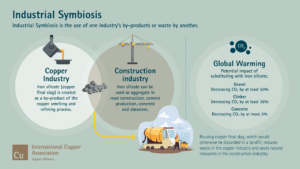

There are many successful examples of industrial symbiosis practices in the copper industry. Iron silicate, a byproduct generated during copper smelting and refining processes, can be used as a safe and sustainable substitute for clinker, gravel and stones for concrete. Research sponsored by the International Copper Association has shown that the global warming potential and primary energy demand associated with the production of cement decrease by at least 36 percent when using iron silicate to partially substitute clinker in cement. Economically, industrial symbiosis benefits both the copper smelters and the concrete producers by turning landfilling into a revenue opportunity. More opportunities arise if other byproducts’ potential is considered in addition to iron silicate. Sulphuric acid, precious metals, lead, tin and nickel sulphate can offer similar sustainability opportunities, further enabling industrial symbiosis and multiplying its benefits.

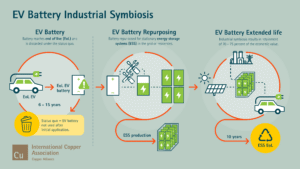

In addition, industrial symbiosis can be implemented via the cross-industry use of secondary resources from end-of-life (EoL) streams. Instead of being recycled, a spent electric vehicle (EV) battery can be repurposed for reuse in the Energy Storage System (ESS) sector, including applications such as electricity grid/off-grid systems, residential and industrial energy storage applications, renewable power plants and thermal generation applications. Given that EV batteries contain considerable amounts of copper (an EV contains a total of 83kg [183lb] of copper), there is high economic value (70 percent of the original battery value) in these spent batteries. This occurs because an EV battery is replaced when 80 percent of its original capacity still remains. According to the European Battery Recycling Association, it would cost about €370 euros ($360) to recycle a typical EV battery (e.g., capacity of 31 kWh and battery density of 4.78 kWh/kg). On the other hand, the cost for a resource producer in Europe to repurpose the battery is zero, as the cost of the repurposing would be borne by the user of the batteries in the second life, who has to compare this with the cost for production of new ones. This makes it even more attractive to both actors to choose repurposing over recycling. From an environmental standpoint, repurposing leads to a longer lifespan for embedded materials, reducing the need to mine for new battery materials. This leads to positive results in other environmental impact categories, such as climate change and resource use (e.g., fossil fuels, minerals and metals). For example, ESS production with repurposed batteries reduces climate change impact by one-third compared to new batteries.

Industrial symbiosis provides a circular, forward-looking proposition. Until it becomes a well-established business practice, there are obstacles to overcome, such as the lack of trust between industries due to geographical distance, absence of data, concerns over the performance of substitute materials or differing regional legal interpretations. Policymakers play a fundamental role in providing solutions to these challenges. Incentivizing industrial symbiosis, introducing performance indicators to reward the best-in-class, and working toward the harmonization of the regional legislation are examples of necessary policy intervention. With all relevant stakeholders on board, industrial symbiosis promises to be a very powerful tool to enable a greener and more circular economy.